COMPANY

Our core competence is skiving and splitting leather, synthetics, rubber, paper and technical textiles – as the market leader we are setting the standards in this field, with machines unrivaled in quality. Fortuna stands for premium quality, best workmanship and state-of-the-art technology.

After analysing your specific requirements, we are part of your team with innovative solutions.

The objective is to develop a facility or machine that is tailored to your requirements and production.

Skiving or splitting machine, standard or custom-made, bell knives or band knives – all products stand out through their durability, highest precision and maximum productivity.

As we are continuously evolving, we can find the optimal solution for every customer.

Our team guarantees individual customer care and combines years of experience with our young colleagues' fresh ideas.

Our service team is at your disposal any time through personal contact or per email regarding technical questions, requests for training, commissioning, repairs or machine maintenance.

True to the motto "We are where our customers are", we maintain an international network of experienced technicians who competently offer support and guidance. This also includes storage of perfectly fitting spare- and working parts.

The development department, located directly on the premises of our company, enables a goal-oriented implementation of customer requirements.

Regular market analyses in combination with state-of-the-art technologies and constant dialogue with our customers secure our technological lead.

Long-term growth for our customers and sustainable development for our environment are part of our company's goals.

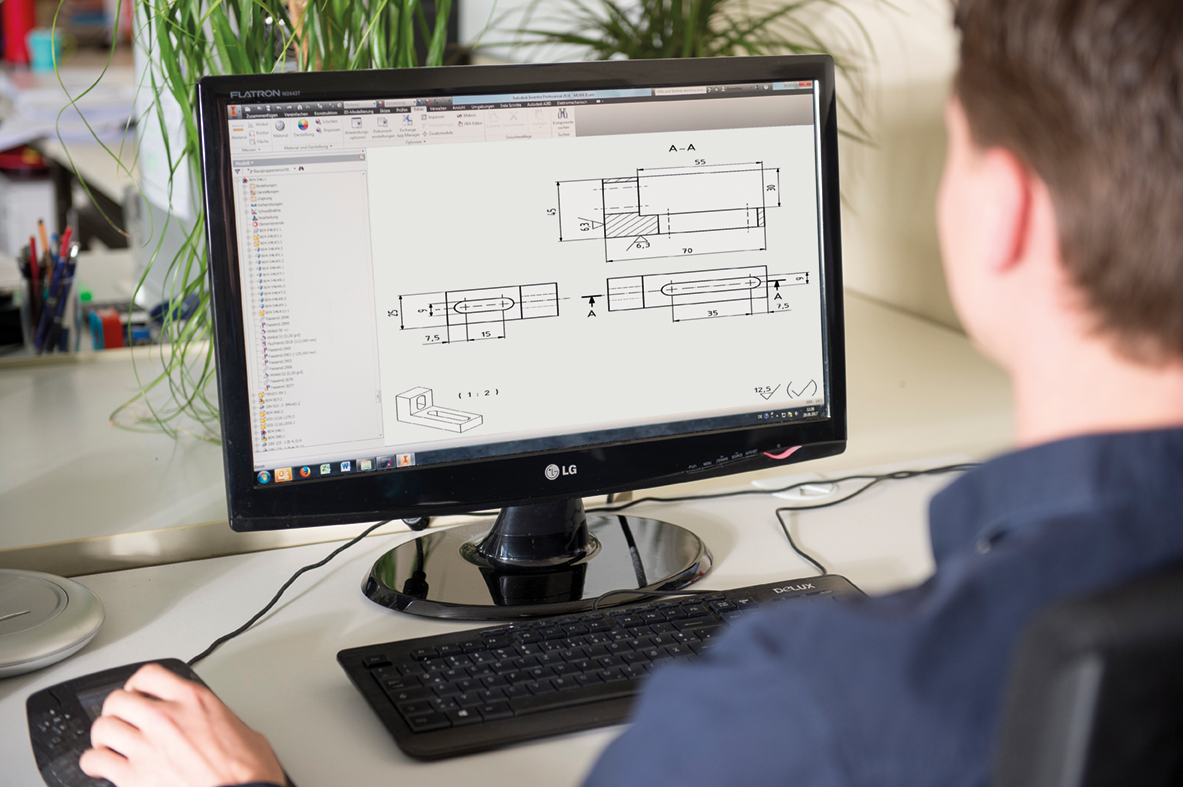

The latest CAD- and construction programmes support the construction of individual parts, assemblies and machines as well as complete equipment.

From minor modifications of standard machines to the construction of new customised machines, we will be delighted to offer you comprehensive advice concerning your specific product application.

We support our customers from idea to prototype. If the machine is designed to be integrated into your existing production line, the requirements analysis as well as project meetings can take place on site in your company.