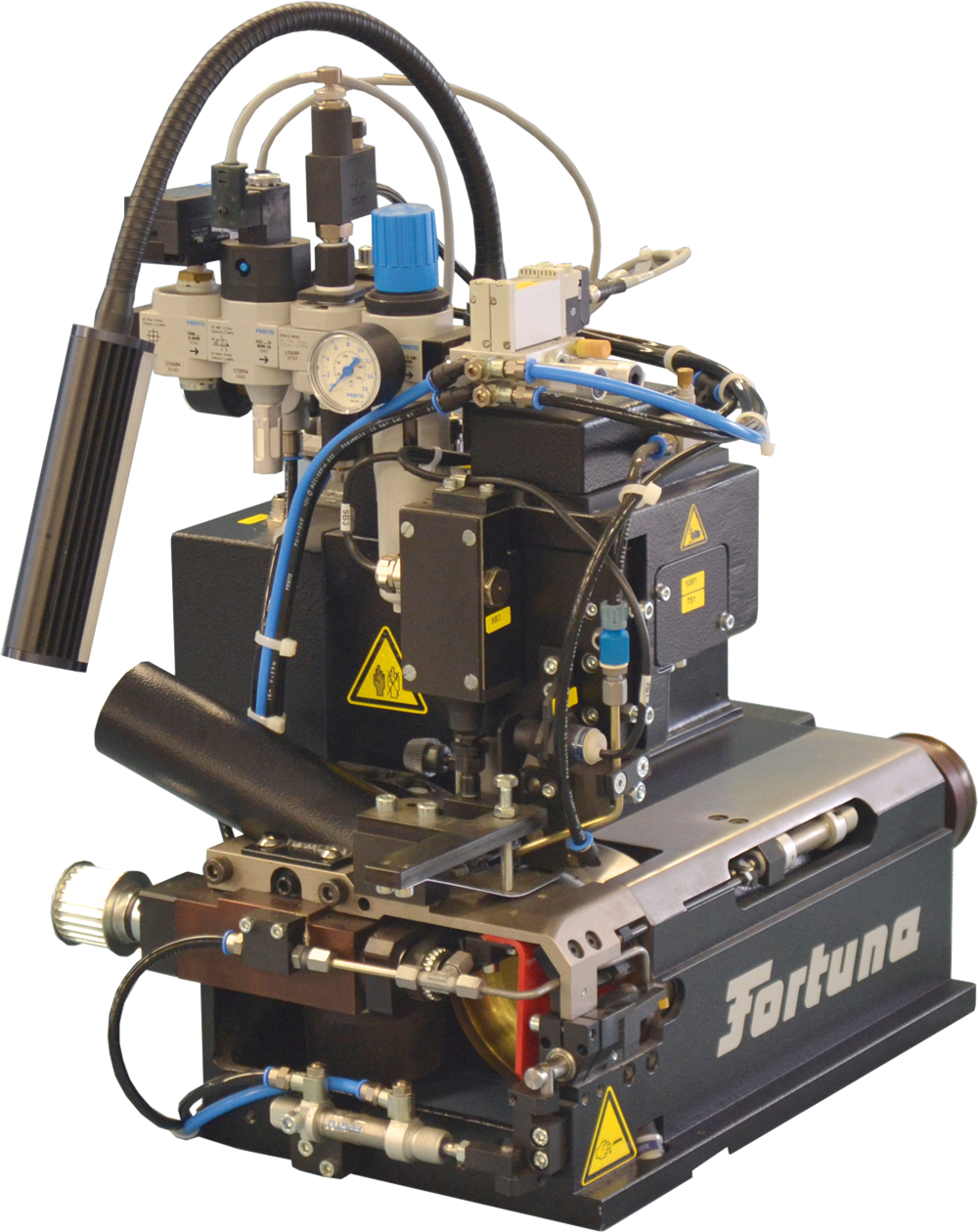

CSP 4

Patented fully automated skiving machine for skiving cardboards to optimize the edge sealing

Concipated for 24/7 operation.

In the skiving machine integrated PLC.

Indivual settings are stored in the skiving machine, not on the operating panel. Thus there is no zero-point setting necessary.

| Technical data | |

| Cardboard thickness (mm) | 0,35 - 1,50 |

| Skiving thickness (mm) | steps of 0,1 |

| Skiving width (mm) | 4,0 – 28,0 |

| Skiving angle | -1° - +3° |

| Remaining cardboard thickness (mm) (minimum skiving thickness) |

0,15 - 0,20 |

MACHINE DESCRIPTION

- 10,4" VGA TFT display with touch screen

- Memory of 10 material types with individual process

- parameter

- Automatic knife positioning, wear out indication and knife speed

- shown on display

- Automatic grinding with free configurable grinding parameters, variable grinding intensity

- Pressure foot positioning with step motor in 0,01 mm resolution with display of skiving angle and skiving thickness

- External driven feed roll by plant, manual positioning with

- indica tion on display

- Accessable und individual adjustable downholder

- Individually programmable start and number of cycles of the cleaning and deburring unit, pressure regulator for deburring disc

- Pneumatic equipment with pressure control, cleaning of grinding disc, deburring wheel and cleaning device,

- air cushion at presser foot to improve sliding characteristics

- Remote service via Internet, several operating languages,

- simple feed update through USB stick directly on the skiving machine

- Operating data capture:

- Error log

- Operating data protocol (optional)

- Preparation for capturing process data

- Interfaces Power Panel:

- 1x RS 232; 3x USB 2.0,

- 1x Ethernet 10/100/1000

- extendable with an interface board

OPTIONS

- For perfect adaption to various operations there are different feet available